Simmons values the importance of measuring methodologies. We continuously invest in gauges, machines and modern instruments for inspection.

Simmons values the importance of measuring methodologies. We continuously invest in gauges, machines and modern instruments for inspection.

.jpg)

With XRF, an X-ray fluorescence spectrometer, SIL can easily ensure samples and production materials meet specifications. It can quantitavely determine alloys' compositions and grades, such as brass, bronze, aluminum, stainless steel. Unlike spark spectrometers, XRF is a non-destructive testing method. .

VMM is a coordinate measuring device combined with a CCD camera, microscope lenses and linear scales in 3 dimensions and a computer. With computer assistance, VMM can capture object's profiles, determine multiple sample dots and calculate geometric dimensions by image matching and provides more accurate position recognition. In addition, VMM can be used as a microscope for detail observation and provides repeat measurement capabilities through programming.

.jpg)

CMM is a mechanical system designed with a movable probe to determine coordinates of points on a workpiece surface. Through mathematical calculation, it can obtain positions, distances, heights, shapes and other geometric information, such as plains, circles, spheres, cylinders, cones, surfaces, etc. SIL is the leader of industry who provides CMM inspection service.

A plating thickness tester operates based on coulometric test method to determine thickness of plating layers on the surface of the iron, copper, and zinc alloy metal. Plating thickness can be used to evaluate a plating’s expected life, corrosion protection or wearing resistance. SIL tests plating thickness to ensure the quality of plating meet spec and compliant with International Standards.

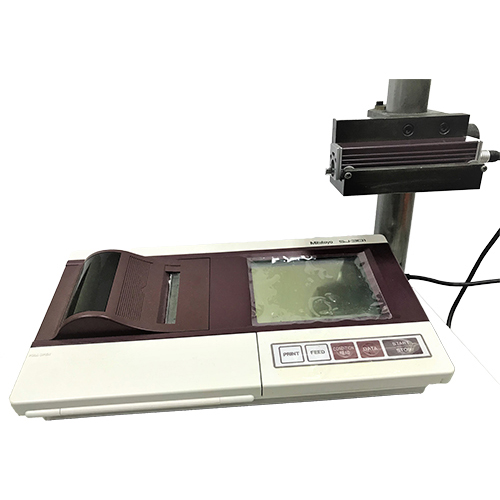

Roughness is an important parameter of a surface condition. A roughness requirement is usually for a particular purpose. Surface roughness tester provides a linear roughness measurement, tracing a mechanical tip along a line of surface to measure roughness. Roughness tester’s measurement results in Ra, Rz and Rrms.

Hardness is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. The result is a number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale.

A go/no-go gauge is an integral part of the quality process that is used in the manufacturing industry to ensure interchangeability of parts between processes or even between different manufacturers.