ABOUT US

ABOUT US

SERVICES

SERVICES

We specialize in Sourcing, Product Development & Engineering, Quality Assurance, and Logistics. From idea to delivery, we ensure reliable solutions, competitive pricing, and on-time performance.

01

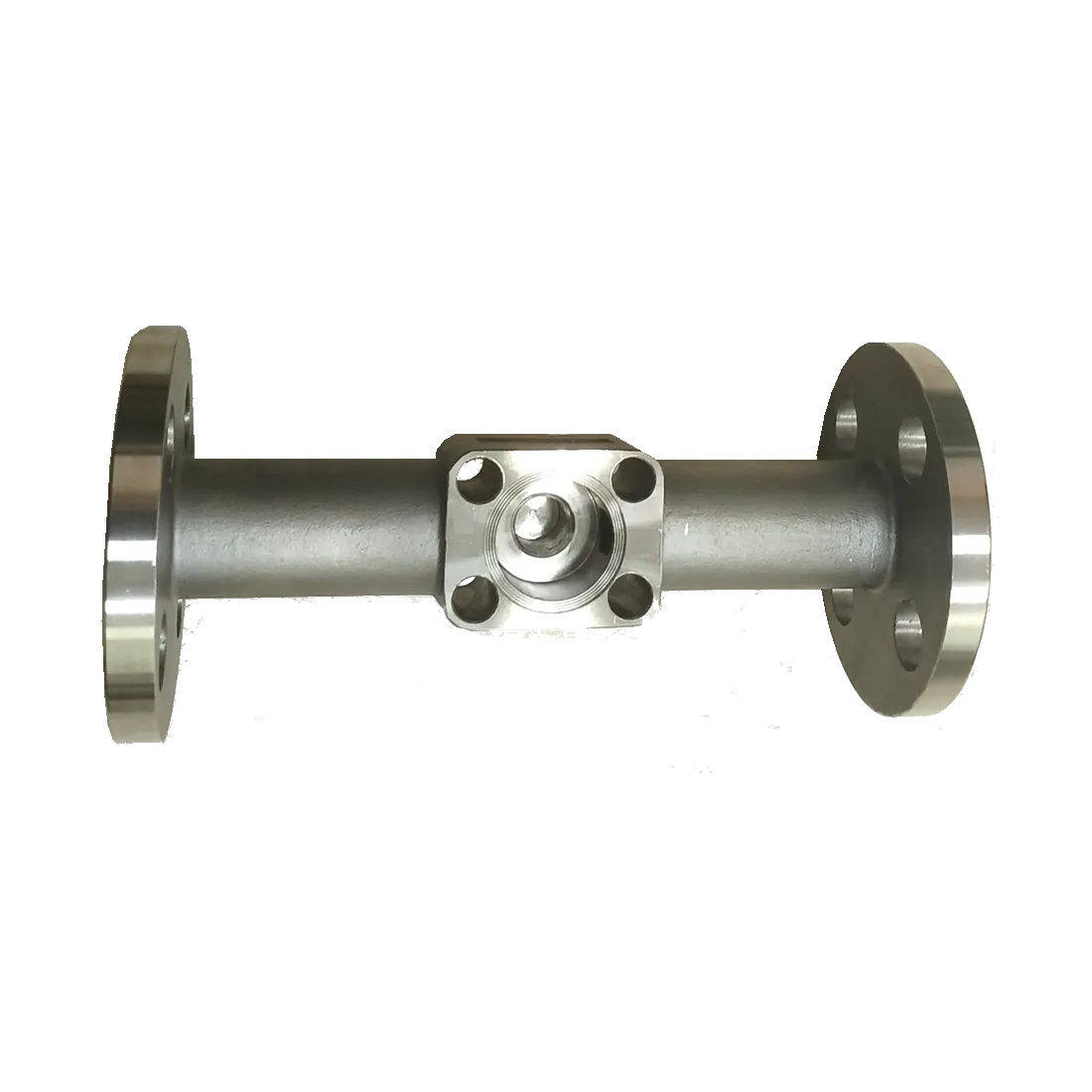

Sourcing

02

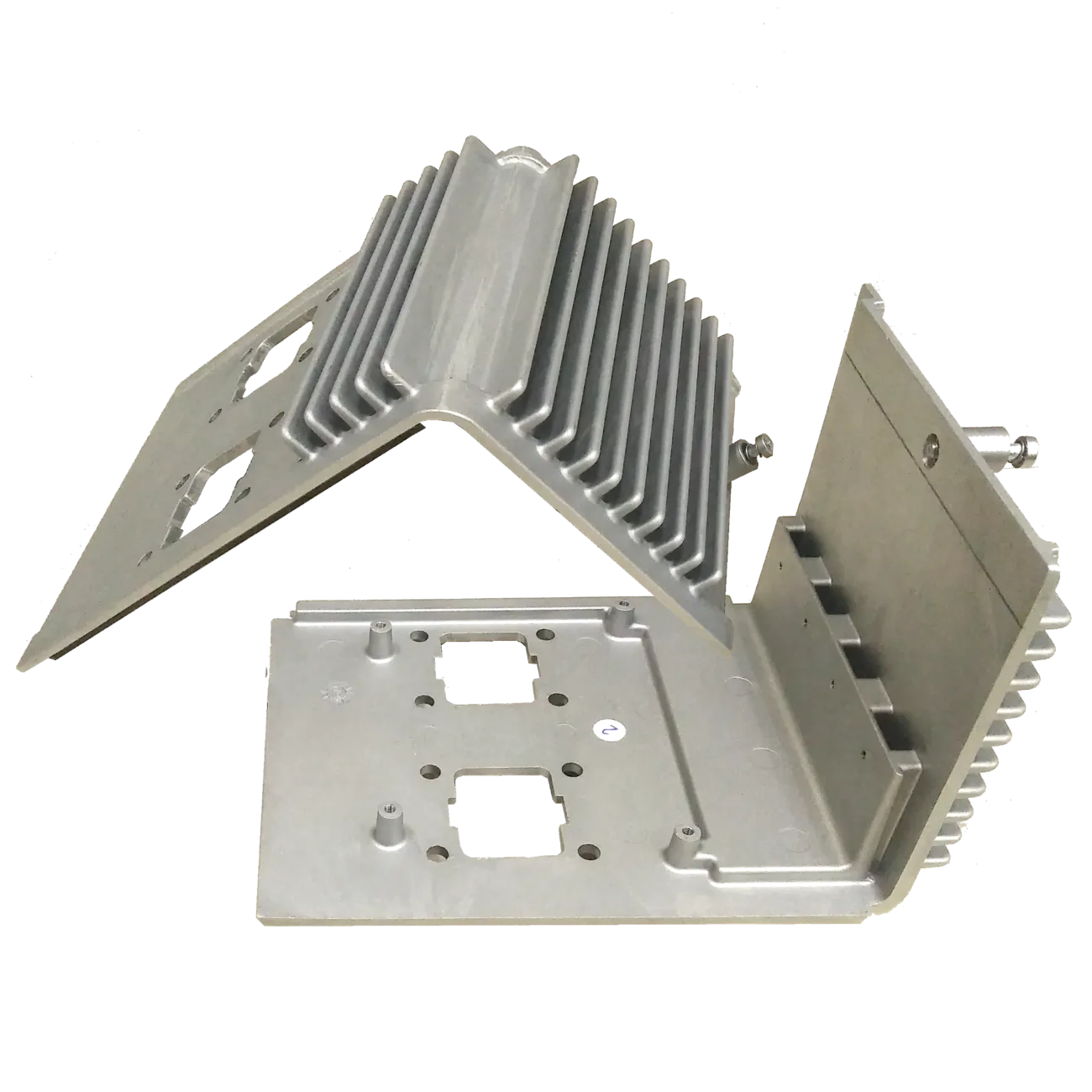

Product

Development

Engineering

03

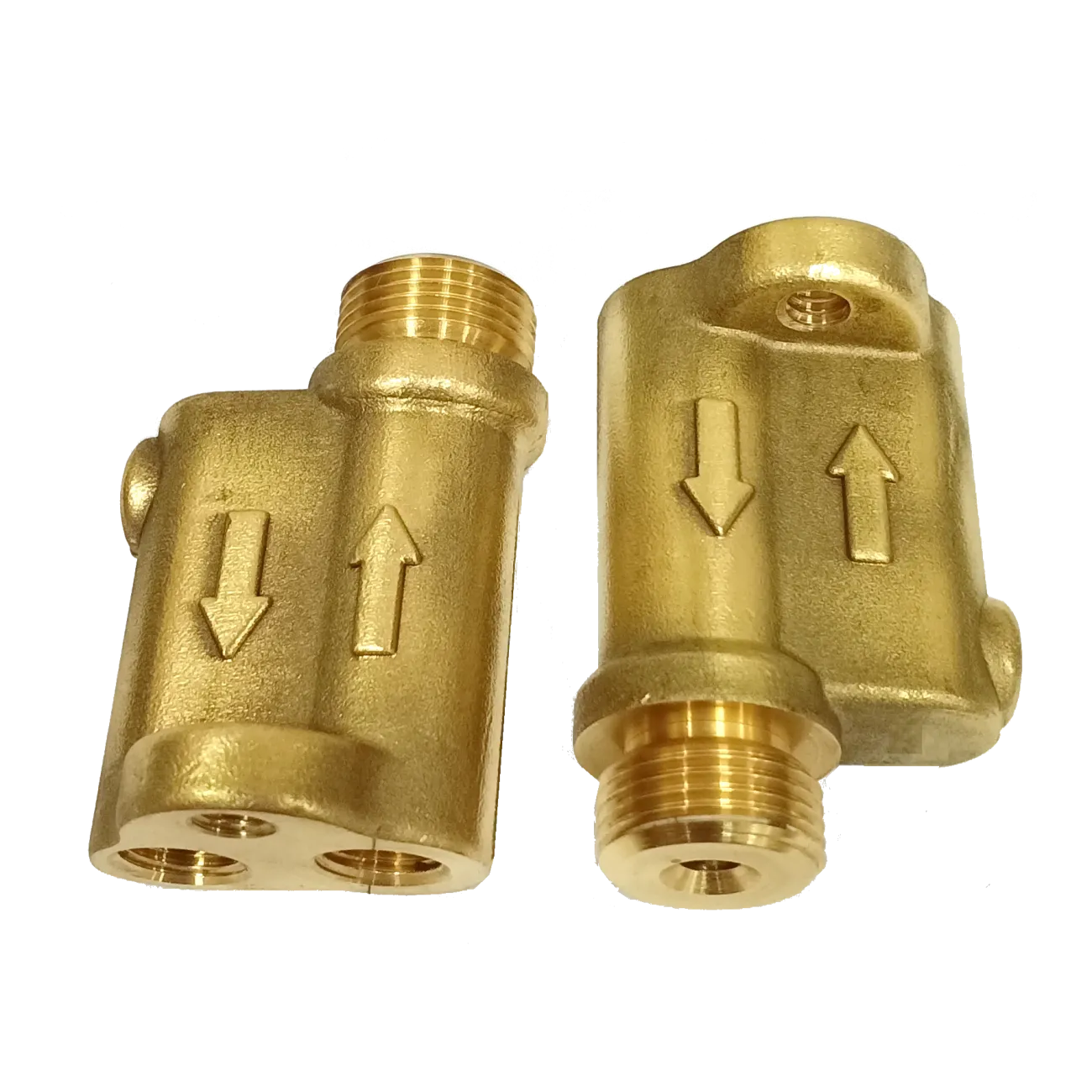

Quality

04